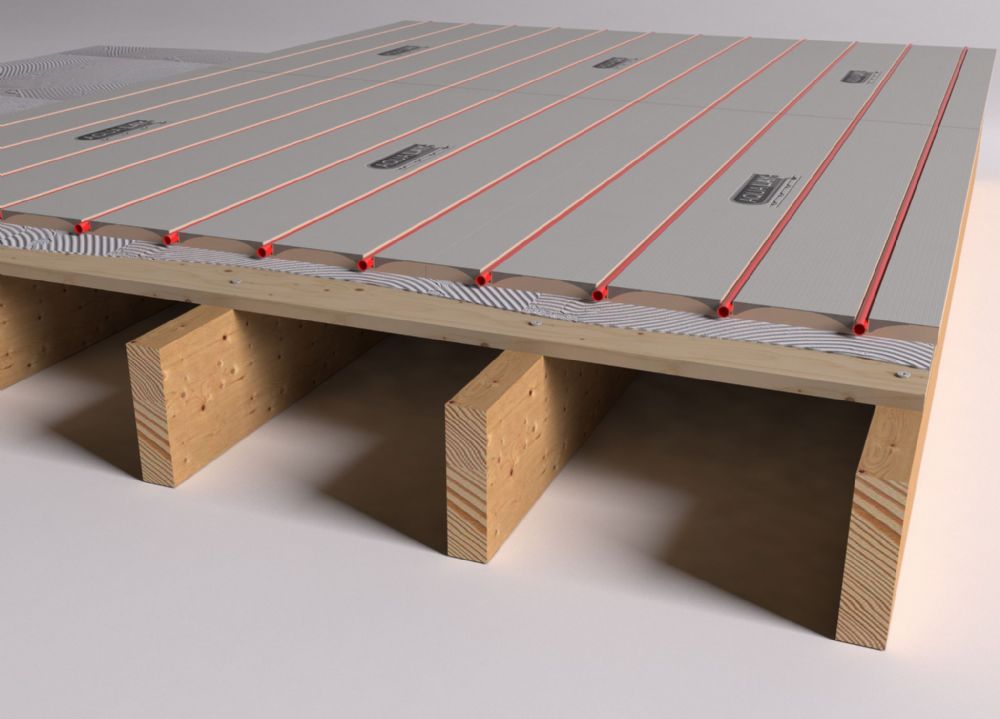

This system uses unique panels that combine the insulation and spreader plate concepts into one solution. The 50mm XPS insulation board has preformed grooves at 200mm intervals, with the whole panel covered with aluminium foil. This helps the items to dissipate heat evenly across the surface above, meaning that there won’t be any cold spots.

Underfloor Heating Systems

Underfloor over lay system

1200 x 600 x 18mm Panel -- 4 grooves at 150mm centres

150mm Pipe Centres -- Ideally suited to standard floor heating applications - Internal rooms insulated to current building standards.

Ideally suited to existing floors where screed is already laid and a low height water system is required - Our grooved foil covered insulation panels are of a unique design and provide many advantages over other insulation products when used with our 12mm pipe warm water underfloor heating systems.

Effectively four products in one, these Insulation Panels comprise a rigid thermal insulation material with radiused grooves at 100mm or 150mm spacings positioned in the upper surface. The upper surface has a metallized foil bonded to it, following into the grooves, which acts as a radiant surface improving heat transfer and reducing system start up times.

The grooves in the insulation securely retain our 12mm or 16mm Pex-Al-Pex pipe in the correct position, eliminating the need for supplementary fixings.

PANEL SIZE: Length- 1200, Width- 600, Depth- 18mm or 25mm(Each panel = 0.72m²)

CONSTRUCTION: Expanded Polystyrene - Grade EPS150

DESIGN: 4 grooves @ 150mm or 100mm centres + radius returns with 3 straight runs at the top of each panel for flow and returns

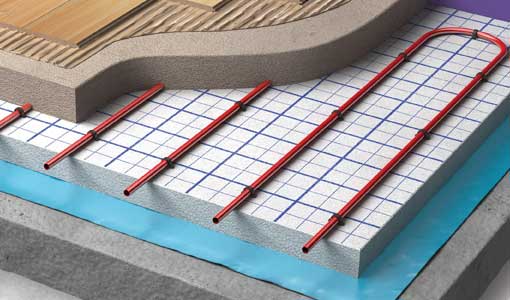

Underfloor system in screed

If you want an efficient setup from your water-based or wet underfloor heating (UFH), and you’re working with a solid floor, then you’ll need to lay the pipework into something that aids the transfer of heat.

That’s where screeds come in. The two most common options are traditional ‘dry’ versions and ‘self-levelling’ types. They not only allow you to prepare the surface for the finished floor covering, but also act to absorb warmth from the UFH pipework and radiate it into the room above.

The screed’s excellent thermal mass helps to maintain comfortable, even temperatures as well as reduce energy use and running costs.

Screed should usually be laid as quickly as possible after the UFH is in place, partly to minimise the risk of damage to the pipework. The system should be pressure-tested for leaks before work begins.

FAST FLOW GAS SERVICES LIMITED (FRN: 1004003) are an introducer appointed representative of Koze Group Ltd, a credit broker not a lender. Koze Group Ltd are authorised and regulated by the Financial Conduct Authority (FRN 811281) registered in England (08357963). We offer finance products from a panel of lenders. Credit subject to age and status.